Last Saturday, Riley and I took our car to compete at Cub Pack 32's pinewood derby race, placing 2nd among the 33 racers submitting cars.

Last Saturday, Riley and I took our car to compete at Cub Pack 32's pinewood derby race, placing 2nd among the 33 racers submitting cars.

The Design

Last year's car didn't make it out of the shaping phase. We got the car down to the shape and added weight, but I forgot to weigh it with the wheels. When I tried to take some wood out of the center with a rotary saw, it went haywire, taking out way too much wood, extremely weakening the car frame, and still coming out overweight. We had to bow out of the race. But not this year.

We started concept work on the car months ago, beginning with me asking Riley what theme we should strive for this year. His vehicles are all named after animals that are not typically known for their fast movement. The Penguin might go fast in the water, but it certainly doesn't through the air of a rocket derby. The Turtle is well known for its slow movement. October's rocket derby featured Riley's Skunk, which took first place. This year's theme? The Squid.

We started concept work on the car months ago, beginning with me asking Riley what theme we should strive for this year. His vehicles are all named after animals that are not typically known for their fast movement. The Penguin might go fast in the water, but it certainly doesn't through the air of a rocket derby. The Turtle is well known for its slow movement. October's rocket derby featured Riley's Skunk, which took first place. This year's theme? The Squid.

We looked online for some squid designs for inspiration, and found a few good ones. We settled on one and I drew up some mock-ups. Riley liked what we came up with, so we pressed forward.

I'm both surprised and not surprised that nobody asked about the process we used to paint the car. All of the cars were styled differently, and Riley's was certainly done with a different technique from the rest.

I'm both surprised and not surprised that nobody asked about the process we used to paint the car. All of the cars were styled differently, and Riley's was certainly done with a different technique from the rest.

After the car was sealed and primed (which Riley helped with), I transferred the squid design using tracing paper onto the primer coat. I then painted the "water" area with frisket, which is a rubber cement-like substance that covers an area that you don't want to paint, then peels off later. With the frisket dry, Riley used an air brush to paint the squid. The use of the airbrush gave the car a fantastic flat paint quality that a regular brush couldn't come close to. There were some other cars that obviously used spraypaint, but didn't include the frisket for detail. Anyway, I'm happy with how that turned out.

I intended to use the frisket again to cover the squid parts and allow Riley to airbrush the water blue, but I was afraid the frisket would take off the squid-colored paint, since we didn't have a lot of time to let it cure to the primer. So instead, I hand-painted the water with some dry-brushed black "seaweed" at the front of the car. This even had the effect of making the blue water look watery, which was a cool side-effect. Overall, I think the car looked great.

I intended to use the frisket again to cover the squid parts and allow Riley to airbrush the water blue, but I was afraid the frisket would take off the squid-colored paint, since we didn't have a lot of time to let it cure to the primer. So instead, I hand-painted the water with some dry-brushed black "seaweed" at the front of the car. This even had the effect of making the blue water look watery, which was a cool side-effect. Overall, I think the car looked great.

The Engineering

The pinewood derby is a hot contest among some scout dads who go into the race for the competition. Some people complain that it becomes a contest between dads, rather than a fun activity for the scouts. I wanted it to be as much of a learning experience for Riley as possible, but it's simply impractical for him to use a band saw at age 9. So I involved him as much as I could, and made sure he understood the science behind the things I was doing to the car, even if he wasn't doing those things directly.

The pinewood derby is a hot contest among some scout dads who go into the race for the competition. Some people complain that it becomes a contest between dads, rather than a fun activity for the scouts. I wanted it to be as much of a learning experience for Riley as possible, but it's simply impractical for him to use a band saw at age 9. So I involved him as much as I could, and made sure he understood the science behind the things I was doing to the car, even if he wasn't doing those things directly.

There were many things we did to make the car go fast. I cut the wood block thinly, with a narrow, "aerodynamic" front, and space in the back for weights. We drilled the axle holes with a tool that guaranteed straight axles, and lifted one wheel entirely from the track to reduce friction. I drilled out holes for the weights in the back of the car, so that the weight could stay on the down-slope for as long as possible to give the car that extra "push". We put  slightly more than the allowed 5 ounces of weight in the car with weighted putty, so that we could slowly remove the extra weight and hit the 5 ounce limit from above, rather than trying to raise the weight from below. The wheels were selected for consistent spin and balance from a large set, then the bores were polished. The axles were polished with increasingly finer sandpaper until they were absent of visible scratches under a magnifying glass. The axles were ever-so-slightly bent to allow them to be aligned in a particular way. The alignment of the car was tested and re-tested to go not completely straight, but to allow the three-wheeled car to effectively track the rail while racing.

slightly more than the allowed 5 ounces of weight in the car with weighted putty, so that we could slowly remove the extra weight and hit the 5 ounce limit from above, rather than trying to raise the weight from below. The wheels were selected for consistent spin and balance from a large set, then the bores were polished. The axles were polished with increasingly finer sandpaper until they were absent of visible scratches under a magnifying glass. The axles were ever-so-slightly bent to allow them to be aligned in a particular way. The alignment of the car was tested and re-tested to go not completely straight, but to allow the three-wheeled car to effectively track the rail while racing.

And that's just the stuff off the top of my head.

Riley helped with many of these things, and watched the things that were not safe for him to do (or he was too nervous about to handle himself). I was particularly proud of him polishing the axles after I told him it was one of the most important parts. He took to the tedious process and did a great job.

Riley helped with many of these things, and watched the things that were not safe for him to do (or he was too nervous about to handle himself). I was particularly proud of him polishing the axles after I told him it was one of the most important parts. He took to the tedious process and did a great job.

Overall, I think you can ask Riley about any aspect of the car, and he'll at least know why we did it, if not having had a hand in it himself. I think this combined with having the chance for us to work on a project together are the most important parts of the derby, and I think we did alright.

The Race

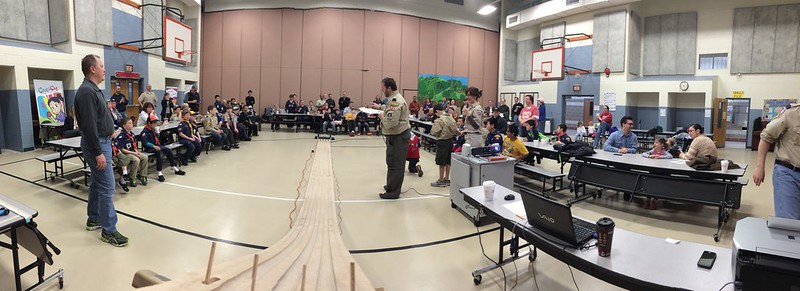

I volunteered to chair the race committee in 2015, so I wanted to be involved in the race this year to know how everything was set up. Our pack has a good track record of smooth events, so I feel getting knowledge passed on from a predecessor is an important part of keeping things running smoothly. As such, I showed up early on the day of registration to help set up the race area, the track and electronics, and registration itself.

I volunteered to chair the race committee in 2015, so I wanted to be involved in the race this year to know how everything was set up. Our pack has a good track record of smooth events, so I feel getting knowledge passed on from a predecessor is an important part of keeping things running smoothly. As such, I showed up early on the day of registration to help set up the race area, the track and electronics, and registration itself.

Our track races four cars at once and uses an electronic timer to detect race starts and finishing places. This is all hooked to a computer with software to schedule races, monitor the race outcomes, and produce the result reports.

On the day of the race, I volunteered to place the cars on the track and release the gate to start the race. This was a lot of fun, but also a bit nerve-wracking, since setting a car on the track at the wrong angle could cause it to lose, and many cars were balanced very weirdly, making them harder to place on the track than you might think. Really, it's a complex job!

On the day of the race, I volunteered to place the cars on the track and release the gate to start the race. This was a lot of fun, but also a bit nerve-wracking, since setting a car on the track at the wrong angle could cause it to lose, and many cars were balanced very weirdly, making them harder to place on the track than you might think. Really, it's a complex job!

The downside of this position is that I could not easily watch the races. There is a mechanism in the release that resets the timer in the electronics, and it was too much of a temptation to reset the release right after the cars crossed the finish line, rather than waiting the appropriate amount of time so that the results could be seen and recorded. The end result is that I didn't actually watch many of the races. In fact, I did watch the very first race (which had Riley's car in it), and I screwed it up, which led me not to watch any of the other races.

That said, from what I heard and what little I did see myself, Riley's car did very well. His average speed on our track was around 233.7 MPH, scaled to the size of real cars. As far as I know, this average speed was faster than anything else on the track. In many of Riley's races, his car seemed to pull away from the other cars on the flat, which seems to defy a car's capabilities. Really, this is all about weight placement and center of gravity, something that Riley and I spent a lot of time talking about and working on.

The races were broken into 3 sets of heats. The first set was all 33 cars racing against each other. These races determined winners within each den. The second set was a semi-final, racing the top 16 cars to obtain the top 4 finishers for the pack results. We ended up with some ties in that second set, so our final set of races had 6 racers.

Riley took first place in his den during the initial heats, which earned him a medal. My dad took video of some of these races. His car placed first in the semi-final, moving on to the final race. In the final set of races, he won the first race, but came in second place for the next two. This was fairly disappointing, considering his consistent first place finishes in all the other races.

Riley took first place in his den during the initial heats, which earned him a medal. My dad took video of some of these races. His car placed first in the semi-final, moving on to the final race. In the final set of races, he won the first race, but came in second place for the next two. This was fairly disappointing, considering his consistent first place finishes in all the other races.

Later, we found that the axle locks (small hex screws we used on the bottom of the car to hold the axles in and at a specific position) on three of the wheels had been ripped out of the bottom of the car. The end of the track has some rubber ramps to keep the cars from shooting off the end, and these probably caused the damage. When we handled the wheels, at least one of the axles was very loose, sliding in and out with very little effort. It's surprising that the car did as well as it did in this condition, and I can only assume that had the axle locks held up, Riley would have passed the first place car, just as it had on every prior race in which they had been matched.

Still, second place is a great showing, and the races at the end were all very, very close. In fact, the race data shows that Riley's car and the winning car had the exact same average speed in the final set of races, down to the tenths of a MPH. It just nosed out the Squid in those last two races, putting him ahead. Good job, Christopher.

There was also a people's choice award, where the scouts vote for their favorite car design. In previous years, only the top car would receive an award. This year, we did first through third place medals, which I think is a great idea, considering how much time scouts and their parents spend on these cars. Riley's friend, Colin, won second place with his classic Batmobile-like car, which was shaped out of the wood block with a Dremel tool. Pretty cool.

There was also a people's choice award, where the scouts vote for their favorite car design. In previous years, only the top car would receive an award. This year, we did first through third place medals, which I think is a great idea, considering how much time scouts and their parents spend on these cars. Riley's friend, Colin, won second place with his classic Batmobile-like car, which was shaped out of the wood block with a Dremel tool. Pretty cool.

Placing in the top three in our pack means that we get to advance to the district race. This year, the Horseshoe Trail District pinewood derby race will be May 10th at the Exton Mall. I'm excited to see Riley's car compete in this cool public venue, and to actually be able to watch the race! We should have adequate time between now and then to repair the damaged axle locks, and to re-tune the wheels to run perfectly again. There are even some small things that we didn't have time for that I think will make a difference in this race against the best cars in the district. It's exciting to get a chance to race again against Christopher's first place car.

Next Year

I have some subtle ideas for improving the race next year. Nothing too fancy, but it could make the experience better for the boys.

Next year, I think I will allow each scout three votes for people's choice instead of just one. It may make tallying a little more complex, but I think it'll even out the distribution. The car that won people's choice this year was another (this is a running theme since we've been in scouts) Minecraft-themed car. It was admittedly a very nicely done car, and in my opinion, deserved first place. But it would be nice to see some leveling-out of the votes. If a kid's first vote goes to the one his friends voted for, then the other two might go to cars based on their actual design. Just a thought.

Also, I'm thinking to make some upgrades and repairs to the track components. The rubber stoppers at the end of the track need replaced. They're very worn and don't always work. We had to put a blanket at the end of the track to catch many of the cars that shot right past the rubber.

I want to do some work on the gate mechanism, so that the gate works the way I've seen on other systems. Our gate is held up by rubber bands. To release the gate, you twist the board that holds the pegs that hold back the cars, and have to hold it down until the race is recorded. What should happen is the gate should be locked in place. When a chuck is pulled, a spring or rubber band should pull the gate open, and it should remain open without holding it until someone lifts it back into place and re-locks it with the chuck. Ideally, the chuck would be controlled by the same computer that records race results.

That's probably enough change, though I'd love to add that instant-replay capability I've seen to our track so that the end of each race can be played in slow-motion on the projector. That would be pretty slick.

Comments

To comment on this post, search for this URL in your ActivityPub client (such as Mastodon):

https://asymptomatic.net/posts/pack-32-pinewood-derby-2014No comments yet. Be the first to reply via ActivityPub!